Subject: Boat’s teak deck treatment and restoration

Date: Tuesday, February 2, 2021

Hello Doc. -

I read your articles and answers and learn a lot, as part as my ongoing attempt to maintain my 28 years boat teak deck.

- it is a high quality teak installed by a reputable Dutch boat builder. It is still in a

reasonable shape, no cracks and no rot that I can see. No water penetration into the glass

sub deck. But…

This is the original deck 3 months after two applications of Semco. Still looked generally good but kind of dry and vulnerable - later it has faded away and the deck seem to stay wet somewhat longer

Nitzan,

I am going to interleave my answers.

If I understand you correctly, it is a teak deck laid over top of fiberglass. If that is correct, the exposed mounting screws would concern me, as they become a conduit for moisture to get down into the likely plywood cored deck. On a traditional teak deck, where the teak is thick enough to allow bungs to be installed over top of countersunk screws. Your teak may not be thick enough for this to be practical. If this is the case, then S-1™ Sealer could be tediously applied around each screw head, helping to seal the screw against water penetration to the core.

Also, the caulking in the seams appears to be starting to get some cracking. If this is truly the case, it would be time to re-caulk the seams. With a teak over fiberglass deck, the seams can’t actually leak. But they can allow water to get under the teak, and possibly to the fasteners which penetrate the fiberglass to mount the teak.

- the original former owners didn’t maintain it well over the 20 years in the Caribbean, I think it was sanded (a big no-no) at least once, removing ~3mm of wood from top.

Sanding is necessary if the teak is to be refinished to a honey color. Sanding or chemical stripping are the only ways to remove the dirt and UV damage that happens to the surface of the wood. It certainly reduces the lifespan of the wood, but is necessary to get the teak back to a honey color. So it is a no-no in that it reduces the life of the teak. But necessary unless you just want to let the teak weather to a gray, or put some type of more durable finish on it. More on that below.

- a thorough washing and soft pad scrubbing shows the deck beauty quite well but it doesn’t last for too long, as it looks, the deck loves to absorb any dirt in the air and rain (a lot of sticky sand/dust from the Sahara is mixed with the rain in the Caribbean).

- Teak is basically a quite soft wood, so I’d like to strengthen, seal and keep it more

durable, where a light wash (and rain) would keep it clean and shows the beauty.

Teak has a Janka scale hardness of about 1000. Certainly not the hardest wood around. But teak is prized for decks for other reasons. First, that it swells and shrinks less from moisture. Second, that it is quite rot resistant, due to the oils. And third, because it has excellent non-skid properties, if left un-coated.

- I’ve tried ‘sealers’ like Semco. Looks nice for few months but then the top level looks like losing the protection. I don’t know the deeper effect.

I haven’t used Semco. But a look at the SDS and I am not surprised at your lack of durability with this product.

- for the last two years I have done multiple experiments on an old marine teak to evaluate the impact of different materials:

• From other sources, understood well that oil based materials will darken the teak - not my intention and preference - I like it as clear light as possible.

• Hallberg-Rassy, probably the most reputable boat builder, recommends ‘Baracol’ - a glycol borate formulation application once a year. I have not tested it yet. As I couldn’t find a small ready made quantity to try out I’ve made my own by mixing and slowly heating Ethylene glycol with borax. - I have not tried it yet.

I can’t imagine why Hallberg-Rassy would recommend a borate in a glycol for preserving teak decks. Borate does have great fungicidal and insecticidal properties. But that is not what damages teak in an outdoor environment.

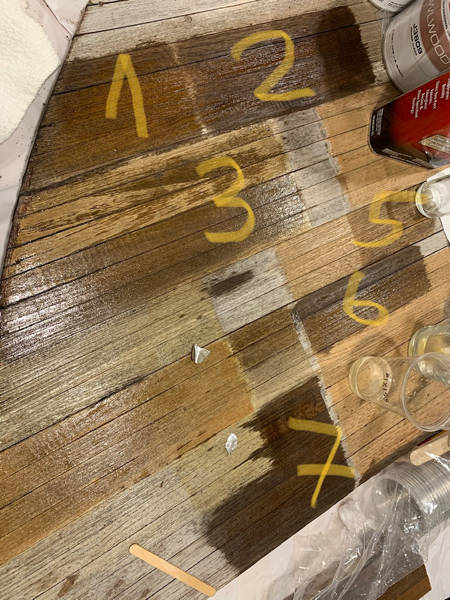

My testing bench… note the darkened are oil and epoxy based materials which I didn’t like. The lightly reddish finish looked better to me.

• With the recommendations to search for water-based polyurethane materials, in order to prevent darkening of the wood, I’ve tried at least 5 products on my testing deck - didn’t like any of these until finally found Urethene water-based for external use by Rust Oleum. The results looks great:

- diluted the first run by ~20% water that improved penetration.

- second was in the original form after about two hours.

The hatch after applying Water-Based Urethane (the rest was not treated)

So after exhausting you with my stories, here are my questions:

1. Am I missing anything in the process?

2. I read at your site about CPES, but wasn’t clear if it is oil or water based? and if it is recommended still in my case to add to the teak durability?

3. What would you recommend?

Thank you

Nitzan

There are several ways to treat exterior teak on a boat.

First, do nothing except make sure that any fasteners or joints are water tight. Doing this allows the wood to weather to a gray, but makes the wood last longer than sanding/stripping and oiling the wood.

Second, sand or strip the wood, and oil it. Unfortunately, while the wood looks good for awhile, the look doesn’t last long, especially in high UV environments. The repeated sanding wears away the teak faster than natural weathering.

Third, put some type of UV resistant coating on the wood. Some teak oils to have UV inhibitors in them. But since the coating is quite thin, they don’t last long. Neither does the oil itself. A thick coating, like a marine varnish (yes, varnish can be adhered to teak if the wood is prepped an primed correctly) or paint does protect the wood from UV decay. However, you lose the very desirable non-skid properties. You can, of course, add non skid materials to the paint or varnish. But they will not be as good at preventing slips as the bare wood. And I don’t think that this is the look you are going for, especially a painted surface.

There are products that attempt to leave the wood natural, yet still provide more UV protection than teak oil. You already have tried the Semco product. The most successful that I know of is Sikkens Cetol line. They fall somewhere between teak oil and varnish in their ability to protect the wood, and their durability.

Personally, I would leave the wood natural. It is the least amount of work, for the second best durability of the wood, without losing the excellent non-skid properties of the bare teak. I wouldn’t recommend doing any of the things that you have tried already, or the penetrating epoxy that we sell. For two reasons. None of them are going to put significant amounts of UV protection on the wood. Meaning they will not significantly extend the life of the wood. And, because you will lose the non-skid characteristics of the bare wood.

The exterior urethane from Rustoleum that you have tried will provide some UV and dirt protection. However, a thin layer of even a high quality urethane will not hold up over time. In high UV, a layer thin enough to still let the wood have most of the qualities of the bare wood will deteriorate relatively quickly in heavy UV.

In the end, you have to pick where you want to compromise. There is not really a win-win situation here. Also, I would check any fasteners that might go into the deck. Sail tracks, stanchions, or the like. Anything where you can remove a screw or through bolt easily, and check to see if the core has gotten wet. If the fittings haven’t been re-bedded in awhile, doing this would be a good chance to check the core. Bedding compound typically lasts from 10–15 years before it needs to be redone. From the images you sent, that would of more concern to me than the teak itself.

Doc

Doc,

Many thanks for the detailed and fast response.

The original teak was 10mm but it is now 7–8mm and many screw heads lost their bungs over time. - If I understood well, you propose

• sealing with S-1 with a thin brush over and around each screw?

- I can definitely do it and appreciate your focus on that.

The subdeck is non-cored pure thick fiberglass and most screws do not penetrate the fiberglass as there are some sub teak plunks in between the fiberglass and the upper deck. There are no deck leaks whatsoever anywhere, including around the chain plates, but I’m going to reseal under the stainless baseplates of all the shrouds at any case.

If there is no deck core, then there is no fear of moisture getting to the core. Moisture wicking down the screw will not damage the teak itself, other than to make it swell and shrink, causing cracks. But if you don’t have cracks now, you are not likely to get them in the future. Given that you don’t need to worry about core rot, I would not bother using the S-1™ around the fasteners.

The caulking is somewhat elevated, but there are very few tiny cracks here and there which I can probably refill -

• would your Dymonic FC or 100 be recommended for this?

Polysulfide has been traditionally used to fill the seams on teak decks. For two reasons. First, its ability to bond to the oily teak. But also, for its resistance to fuel spills. This is primarily a concern around fuel fillers, so Dymonic® FC would be the recommended product, except for around fuel fillers. With proper surface prep, it would stick fine to either the old caulk or the teak.

As for the elevation, except in significant areas of elevation where I think of shaving the excess, I thought of leaving it as-is as long as it has no cracks or separation from the teak plunks (there isn’t as far as I could see) - it can help in maintaining a higher non skidding surface. Would you agree?

If you want to make the teak last as long as possible, then don’t sand any more than necessary. If the teak is quite ridged, some sanding might be called for, since you are losing surface area. There is less wood for your feet to grip to with very ridged wood. Also, if you want the teak to get to a nice honey color, you will have to sand. But that reduces the amount of teak that is left. Compromises.

• Would you also recommend the Dymonic for the rebedding under any deck hardware?

Dymonic® FC would be a good choice for re-bedding any hardware.

As for the future UV exposure. After all the years in the Caribbean, the boat is on her way to New England where the conditions are somewhat closer to where she was born, by Contest Yachts in the North Sea so I hope that at least the UV damages will be reduced as well as the combination of high temperatures and moisture.

Will try the Sikkens Cetol as well. Apart from my interest in keeping a good look of the natural teak deck, my major concern is to maintain the entire deck in the best integrated condition and completely sealed. Will compare it to the Rust Oleum that as indicated, so far showed the best penetration without external film and kept the teak color as original as possible.

Again, many thanks!

Nitzan

Unless you provide a significant UV barrier, sealing the wood with the Rustoleum or even Cetol is not going to extend the life of the teak too much. Some, but you have to decide if the work is worth the effort. Boats are always a trade off between maintenance and enjoyment.

Doc